1. Protection from overcurrent

DC circuit breakers are primarily used to protect circuits from overcurrent conditions. Overcurrent can cause components in a circuit to overheat, or even cause fires, among other serious consequences. By disconnecting power in a timely manner, DC circuit breakers help prevent equipment damage and extend the life of the system. In addition, in the event of a short circuit or equipment failure, DC circuit breakers are able to respond quickly to ensure the safety and stability of the circuit. Effective overcurrent protection is critical to the overall safety of electrical systems, especially in high-power applications.

2. Safety

In direct current applications, circuit breaker safety is particularly important because the arc of direct current is more obvious when disconnected than that of alternating current. This arc can cause equipment damage or cause fires, so DC circuit breakers are designed with this in mind and can effectively suppress the generation of arcs. By ensuring the safe disconnection of the circuit, DC circuit breakers provide additional safety for operators and equipment. In addition, in certain application scenarios, such as electric vehicles and solar energy systems, safety is particularly important to avoid potential dangers.

3. Reliable disconnection

DC circuit breakers provide reliable power disconnection when a circuit fails. This disconnection function ensures that technicians can safely handle electrical equipment without worrying about the risk of electric shock when performing maintenance or repairs. Whether due to equipment failure or human error, DC circuit breakers can quickly cut off power and avoid wider damage. At the same time, a reliable disconnection mechanism also helps maintain the stability of the system, ensuring that other parts can still work normally in the event of a fault, increasing the reliability of the system.

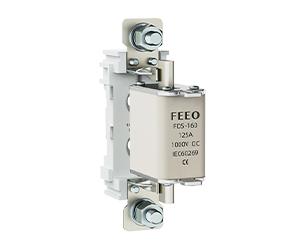

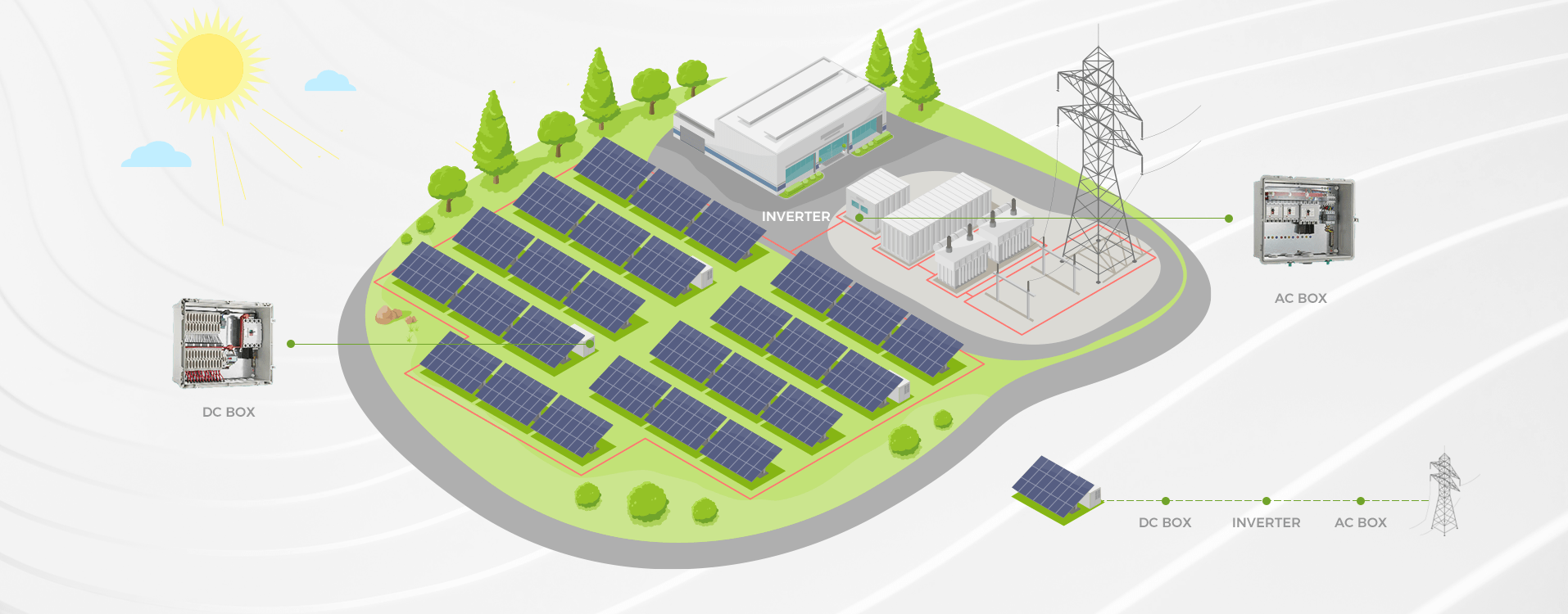

4. Specific applications

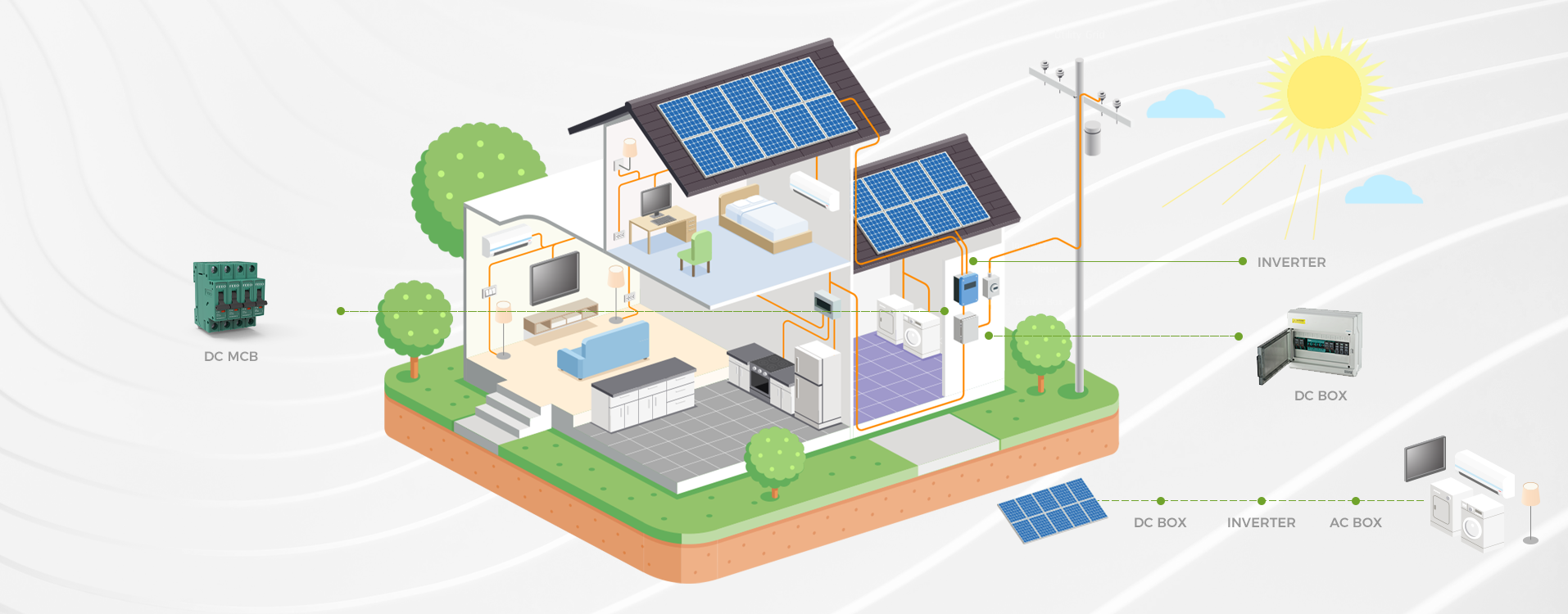

DC circuit breakers play an important role in many specific applications, such as solar power generation systems, electric vehicles, and battery energy storage systems. In these applications, direct current is the main form of power, so specially designed circuit breakers are required to handle specific voltage and current characteristics. DC circuit breakers can not only effectively protect the system, but also optimize performance and ensure stable operation under high load conditions. With the popularity of renewable energy, the demand for DC circuit breakers is also growing, becoming an indispensable part of modern electrical design.

5. Voltage level compatibility

DC circuit breakers are designed with specific voltage and current levels in mind to ensure their effective performance in DC systems. In different applications, DC circuit breakers are able to cope with a variety of working conditions from low voltage to high voltage to ensure safe and reliable operation. This voltage compatibility enables DC circuit breakers to be widely used in various power systems to meet different needs. At the same time, the design also takes into account the stability and durability under long-term use, ensuring that the circuit breaker can work stably under various environmental conditions.

6. Low maintenance

Many DC circuit breakers are designed as low-maintenance products, which is particularly important for use in remote or difficult-to-access locations. This means that after long-term use, the circuit breaker can still maintain good performance without frequent inspection or replacement of parts. This low-maintenance feature reduces operating costs and saves time and human resources, making maintenance work easier. Especially in large power systems or distributed power generation facilities, low-maintenance DC circuit breakers can significantly improve the operating efficiency and reliability of the system.

7. Compact design

DC circuit breakers are usually designed to be more compact than traditional AC circuit breakers, which makes them easy to install even when space is limited. This compact design not only helps save installation space, but also improves the layout flexibility of the overall system. Especially in electric vehicles and high-efficiency solar systems, the effective use of space is particularly important. In addition, compact design usually means that more functions can be integrated into a smaller chassis, thereby improving the overall performance and user experience of the equipment and meeting the diverse needs of modern electrical systems.

Q1: Can I use an AC circuit breaker in a DC circuit?

A1:Using AC circuit breakers in DC circuits is generally not recommended because AC circuit breakers are designed to handle AC power and can naturally return to zero in each cycle to help extinguish the arc. DC power does not return to zero, making arcs more difficult to extinguish, posing a safety hazard. In addition, the voltage and tripping mechanism of AC circuit breakers are not suitable for DC applications, which may result in failure to disconnect reliably in the event of a fault. Therefore, it is critical to ensure that circuit breakers designed for this are used in DC circuits.

Q2: How do I choose the right DC circuit breaker for my application?

A2:When choosing a suitable DC circuit breaker, you need to consider the following factors: first, make sure the voltage level meets the system requirements; second, choose the current level suitable for the maximum load; check the interruption capacity to ensure that the fault current can be safely cut off; consider the load type (such as resistive or inductive), and evaluate the installation environment (temperature, humidity, etc.). Finally, confirm that the relevant safety standards are met.

Q3: How often should I check my DC circuit breaker?

A3:It is recommended to inspect DC circuit breakers regularly, usually every 6 months to 1 year. The inspection should include appearance, connection tightness, and whether there is obvious wear or damage. In addition, it should be inspected immediately after a system failure or load change. Regular maintenance helps ensure the safety and reliability of the equipment and avoid potential problems.