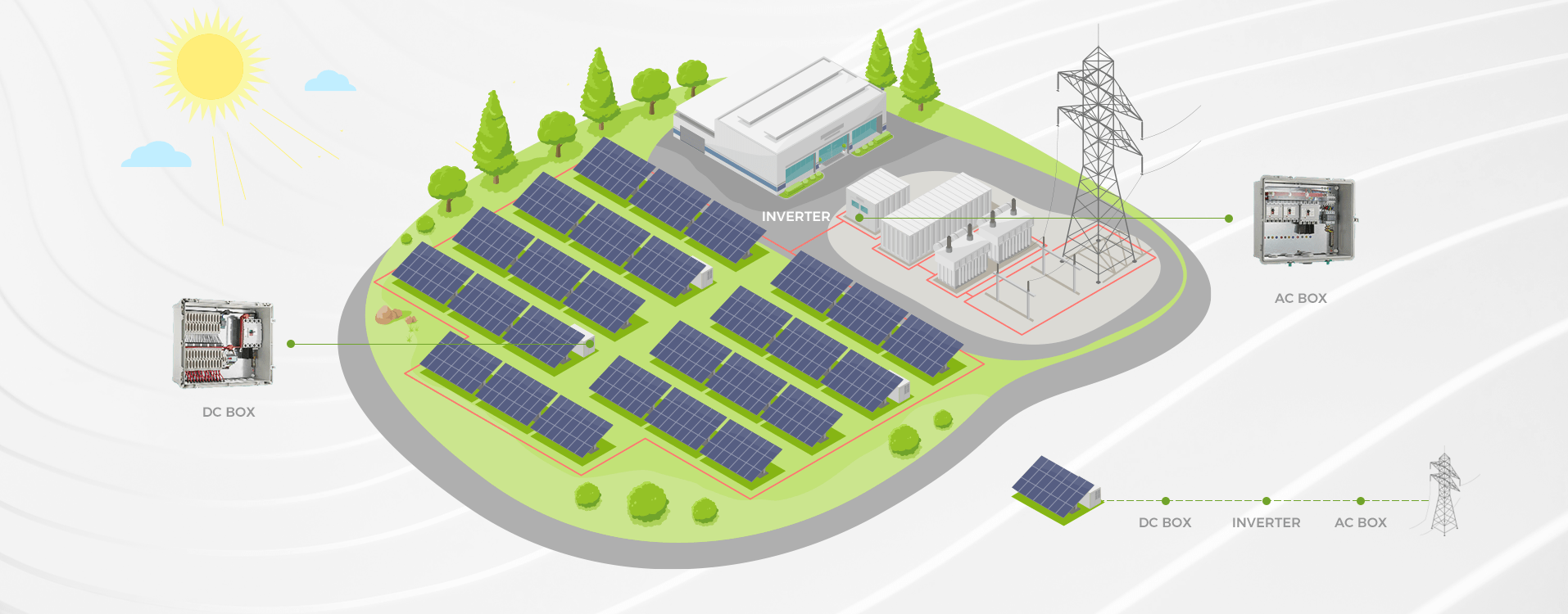

Key Technologies for Efficient PV O&M

1. Smart Monitoring and Data Analysis

Modern PV plants rely on SCADA (Supervisory Control and Data Acquisition) systems and IoT sensors to monitor real-time performance. AI-driven analytics can detect underperforming modules, soiling, or faults, enabling predictive maintenance and minimizing downtime.

2. Regular Cleaning and Dust Prevention

Dust, bird droppings, and snow accumulation can reduce efficiency by 5-20%. Automated cleaning robots, water-free cleaning systems, and anti-soiling coatings help maintain optimal energy output.

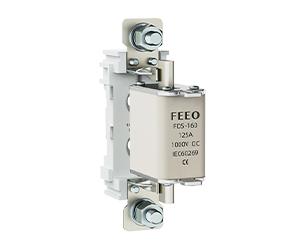

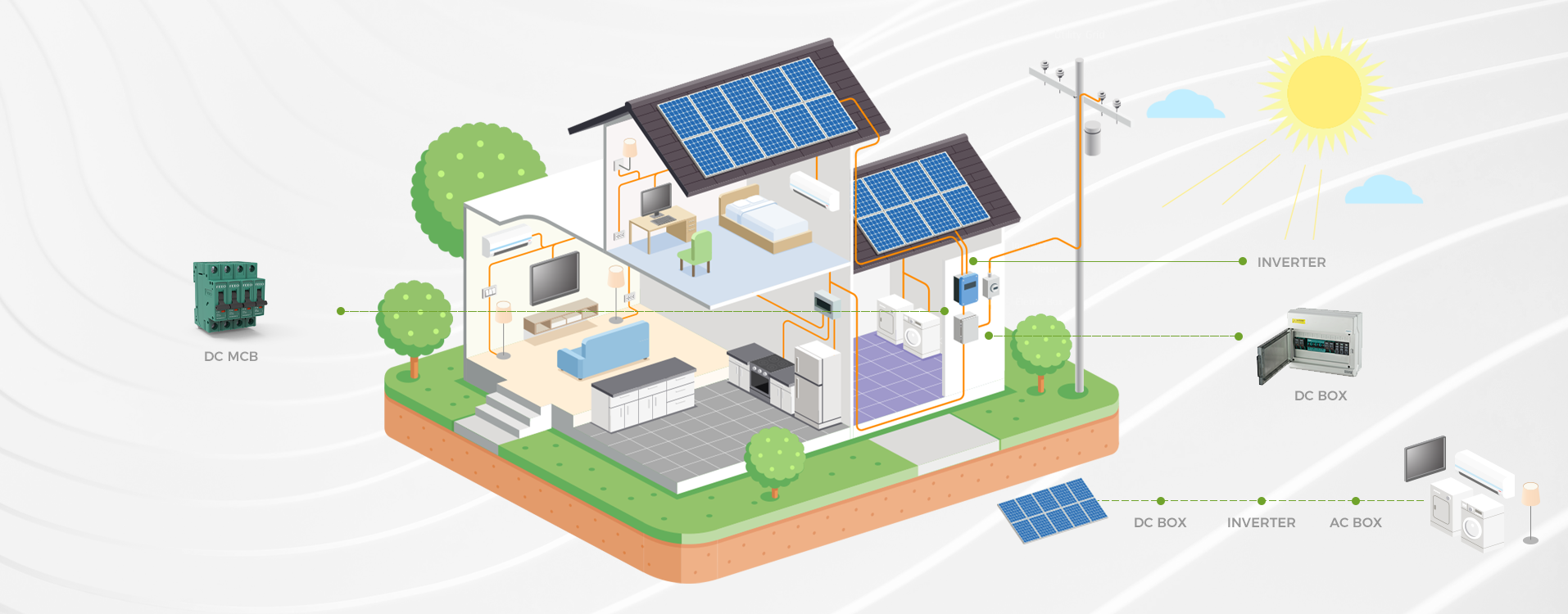

3. Inverter and Component Maintenance

Inverters, the "heart" of PV systems, require regular inspection to prevent failures. Thermal imaging and IV curve testing help identify hotspots, loose connections, or degradation in solar panels.

4. Vegetation and Pest Control

Overgrown weeds and rodents can damage cables and structures. Routine vegetation management and pest-proof wiring ensure system longevity.

5. Weather and Disaster Preparedness

Extreme weather (hail, storms, high winds) can impact PV systems. Reinforced mounting structures, lightning protection, and emergency response plans mitigate risks.

Best Practices for Long-Term Stability

Preventive Maintenance: Schedule quarterly inspections to detect issues early.

Performance Benchmarking: Compare actual output with expected generation to identify deviations.

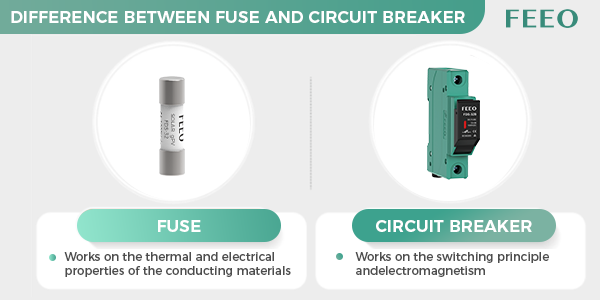

Spare Parts Management: Keep critical components (inverters, fuses, connectors) in stock to reduce repair delays.

Staff Training: Well-trained technicians improve troubleshooting efficiency.

Conclusion

A well-maintained PV power station can operate efficiently for 25+ years, ensuring stable returns on investment. By adopting smart monitoring, automated cleaning, predictive maintenance, and disaster preparedness, operators can maximize energy yield and extend system lifespan. The future of PV O&M lies in AI, robotics, and advanced analytics, making solar energy a reliable and profitable long-term investment.