2023.11.04

Introduction

DC miniature circuit breakers (MCBs) are essential components in electrical systems that protect against overcurrent and short circuits. Unlike their AC counterparts, DC MCBs are designed to handle direct current (DC) flow. This article aims to provide a comprehensive understanding of DC MCBs, including their working principles, construction, ratings, applications, and maintenance.

Working Principles

DC MCBs operate on the principle of thermal and magnetic tripping. They consist of a bimetallic strip that bends due to the heat generated by the current passing through it. As the current exceeds the rated threshold, the bimetallic strip bends and triggers the trip mechanism, opening the circuit and interrupting the current flow.

Additionally, DC MCBs employ a magnetic tripping mechanism. When a high-intensity short circuit occurs, a strong magnetic field is created, which attracts the armature and releases the mechanical latch, causing the contacts to open.

Construction

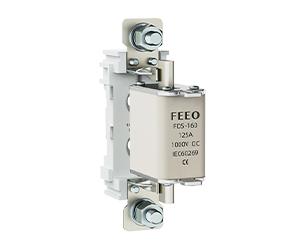

DC MCBs are typically housed in a molded case made of durable materials such as thermosetting plastics. Inside the case, there are three main components: the operating mechanism, the trip unit, and the current-carrying contacts. The operating mechanism includes the handle, latch, and trip mechanism.

The trip unit comprises the bimetallic strip and the magnetic coil. The bimetallic strip provides thermal protection, while the magnetic coil provides magnetic tripping during short circuits. The current-carrying contacts are made of high-quality materials to ensure efficient current flow and to withstand frequent operations.

Ratings

DC MCBs are available in various ratings, including voltage ratings, current ratings, and breaking capacity. The voltage rating indicates the maximum DC voltage that the MCB can safely handle. Common voltage ratings range from 12V to 1000V.

The current rating specifies the maximum continuous current that the MCB can carry without tripping. It is crucial to select an MCB with an appropriate current rating to ensure safe and reliable operation.

The breaking capacity, also known as interrupting rating, represents the maximum fault current that the MCB can safely interrupt without causing damage. It is essential to choose an MCB with a breaking capacity that exceeds the potential fault current in the system.

Applications

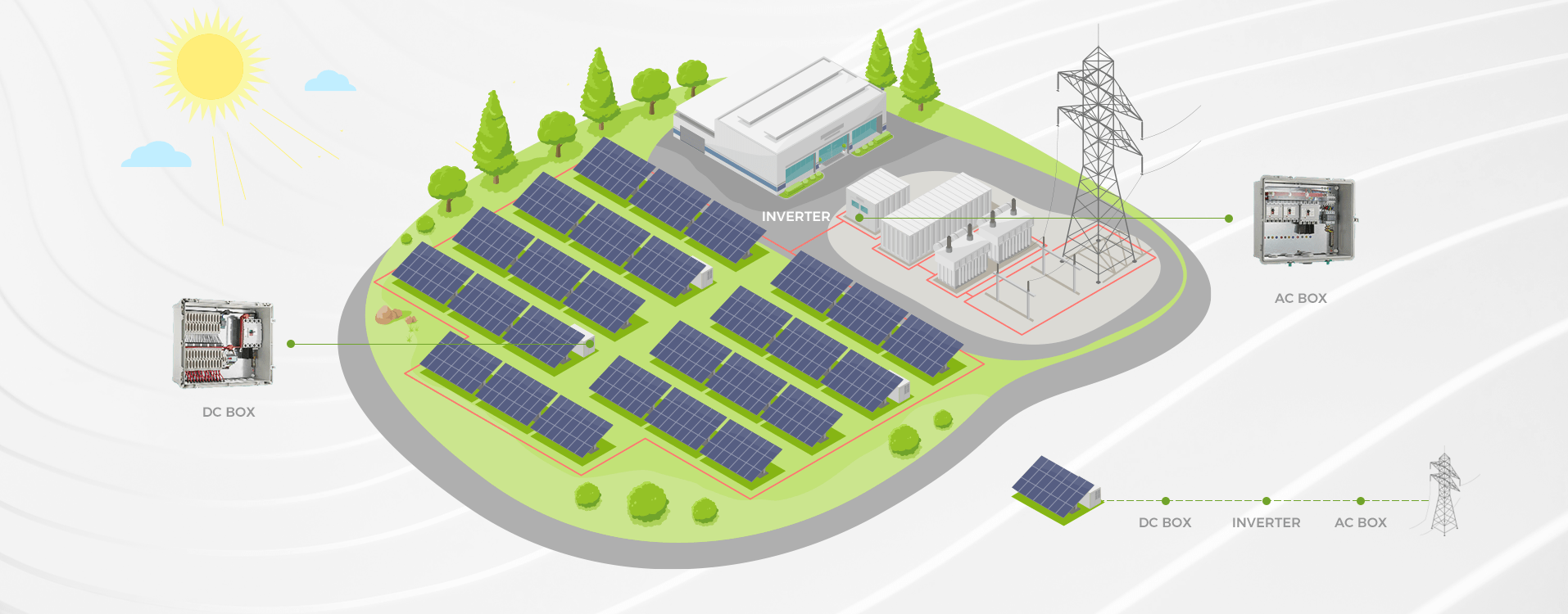

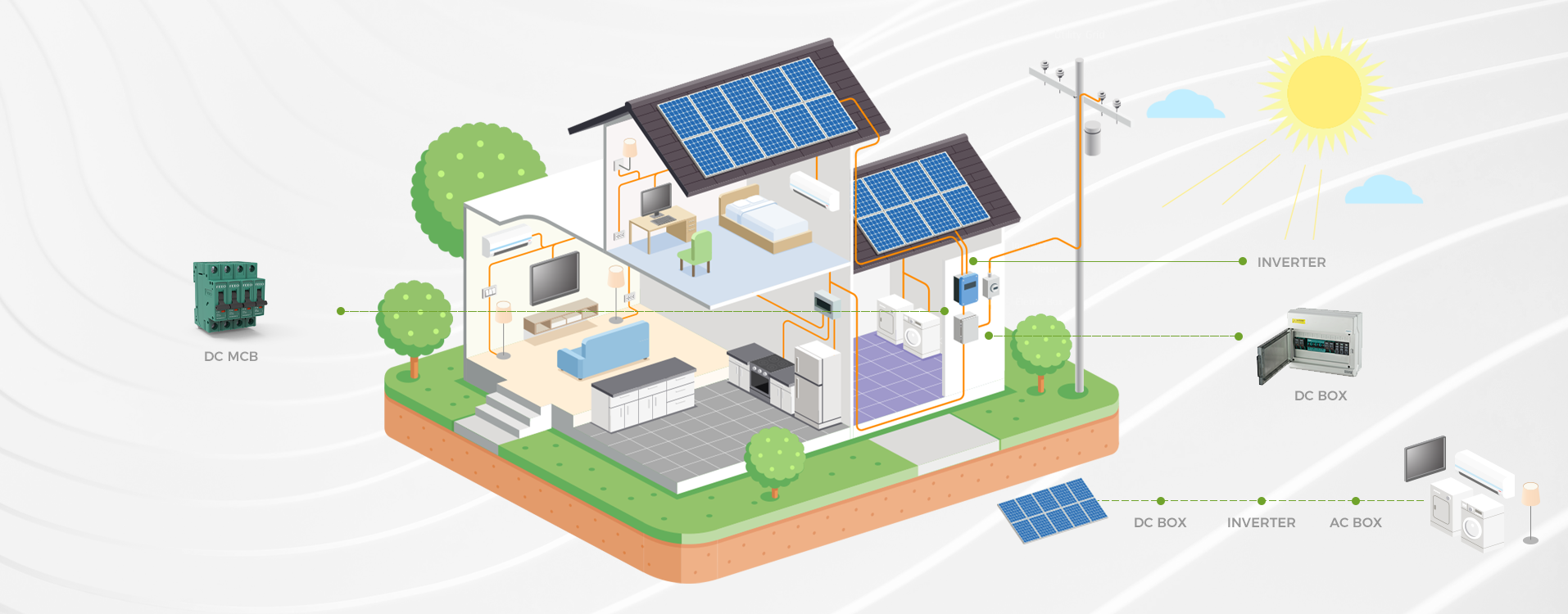

DC MCBs find applications in a wide range of industries, including renewable energy systems, automotive, marine, telecommunications, and industrial automation. They protect crucial equipment, such as solar panels, batteries, motors, and control circuits, from overcurrent and short circuits.

In renewable energy systems, DC MCBs are used to protect photovoltaic arrays and battery banks. In the automotive industry, they safeguard electrical systems in electric vehicles and hybrid cars. In marine applications, DC MCBs protect against electrical faults in ships and yachts.

Maintenance and Safety

Proper maintenance is crucial to ensure the reliable operation of DC MCBs. Regular inspections should be conducted to check for any signs of damage, loose connections, or overheating. The MCBs should be operated within their specified ratings and not overloaded.

Safety precautions must be followed when working with DC MCBs. Before performing any maintenance or installation, the power supply should be disconnected. It is also essential to use appropriate personal protective equipment (PPE) and follow established electrical safety guidelines.

Conclusion

DC MCBs play a vital role in protecting electrical systems from overcurrent and short circuits. Understanding their working principles, construction, ratings, applications, and maintenance is crucial for ensuring safe and reliable operation. By adhering to proper installation and maintenance practices, along with following necessary safety precautions, DC MCBs can effectively safeguard electrical equipment in various industries.