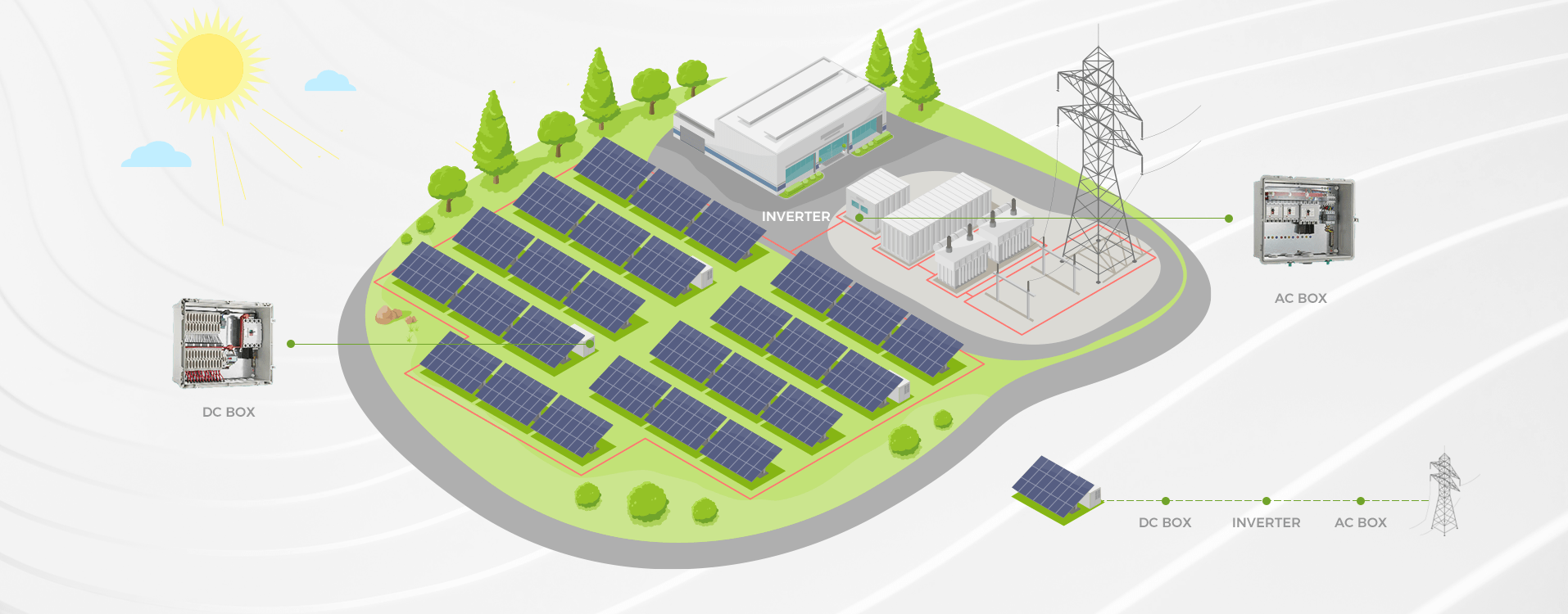

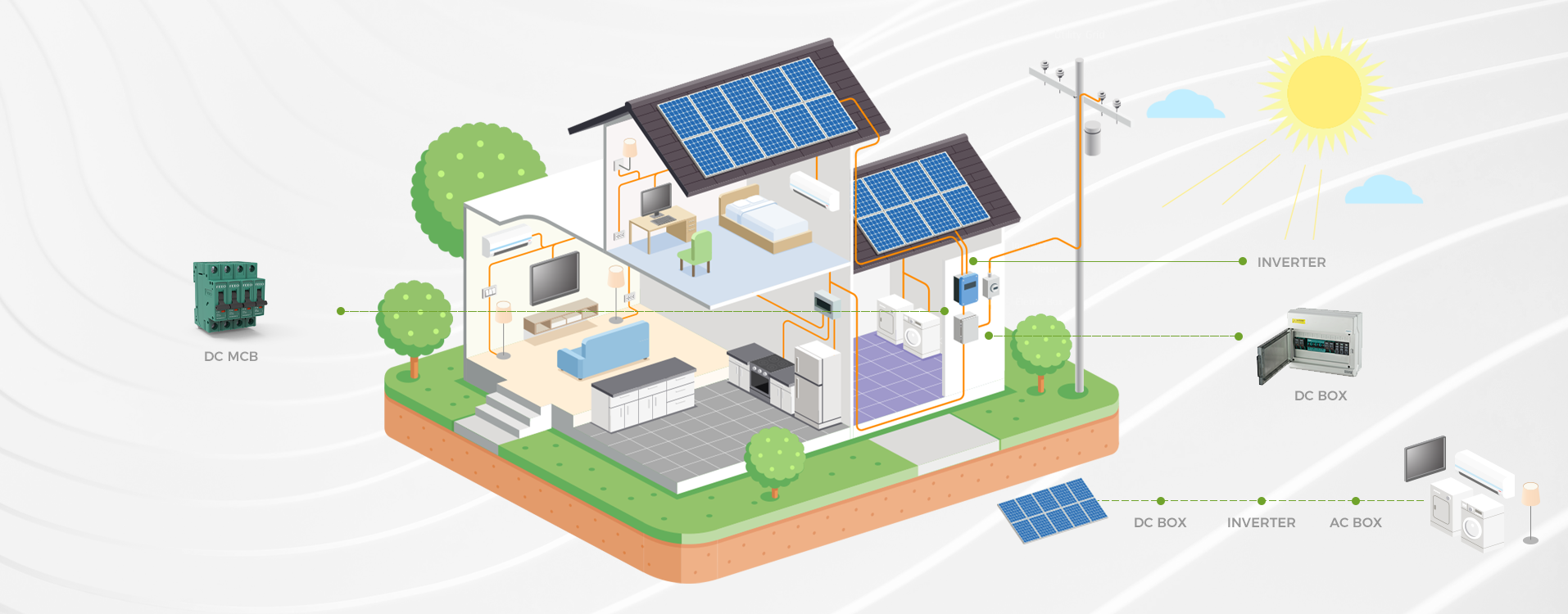

As the world continues to transition towards renewable energy, photovoltaic (PV) systems have become an essential part of the global energy landscape. In this article, we will delve into the world of DC fuses, an integral component of PV systems, to help beginners understand their importance and functionality. We'll discuss what a DC fuse is, the different types available, how to determine the appropriate fuse size, and the differences between AC and DC fuses.

What is a DC Fuse?

A Direct Current (DC) fuse is a safety device used in electrical circuits to protect against overcurrent, which can lead to overheating, fire, and equipment damage. It consists of a wire or metal strip that melts and breaks the circuit when the current flowing through it exceeds a specified rating. By interrupting the flow of electricity, a DC fuse prevents damage to the circuit components and ensures the overall safety of the system.

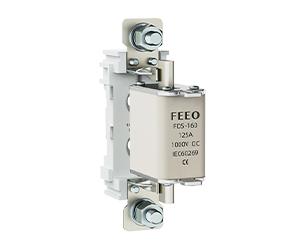

DC fuses are specifically designed for use in direct current circuits, such as those found in solar PV systems, battery banks, and electric vehicles. They play a critical role in safeguarding these systems against potential hazards and maintaining theirefficient operation.

DC Fuse Types

There are several types of DC fuses available, each with distinct characteristics and applications. Some common types include:

1.

Cartridge Fuses: These cylindrical fuses feature a metal cap on each end and a fusible link enclosed within a glass or ceramic tube. Cartridge fuses are available in various sizes and ratings and are typically used in automotive, residential, and industrial applications.

2.

Blade Fuses: Widely used in automotive and low-voltage applications, blade fuses consist of a flat, thin metal strip with a fusible link. They are designed to plug into a fuse holder or fuse block and are easily replaceable. Blade fuses are color-coded to indicate their amperage rating, making them simple to identify.

3.

Resettable Fuses (PTCs): Unlike traditional fuses, resettable fuses (also known as polymeric positive temperature coefficient or PPTC devices) do not require replacement after a fault. They automatically reset once the overcurrent condition is resolved, and the temperature of the device has returned to a safe level. PTCs are commonly used in low-voltage DC circuits, such as consumer electronics and battery protection.

4.

High-Voltage DC Fuses: These fuses are specifically designed for high-voltage DC applications, such as solar PV systems and electric vehicle charging stations. They often feature a more robust construction and higher interrupting ratings than standard DC fuses to handle the high energy levels involved in these systems.

How to Determine DC Fuse Size

Selecting the appropriate fuse size is crucial for ensuring the safety and efficiency of an electrical circuit. To determine the correct DC fuse size, follow these steps:

1.

Identify the Maximum Operating Current: Determine the maximum current expected to flow through the circuit under normal operating conditions. For solar PV systems, this can be found by multiplying the short-circuit current (Isc) of the solar panels by a safety factor, typically 1.25. For other applications, refer to the manufacturer's specifications or consult an expert.

2.

Consider the Fuse Rating: The fuse rating should be greater than the maximum operating current to avoid nuisance tripping during normal operation. However, it should not be too high, as this may compromise the protection provided by the fuse. As a general rule, select a fuse with a rating between 125% and 150% of the maximum operating current.

3.

Check the Interrupting Rating: The interrupting rating (also known as breaking capacity) of a fuse indicates its ability to safely interrupt the flow of current in the event of a fault. Ensure that the fuse's interrupting rating is equal to or greater than the maximum short-circuit current that could occur in the circuit.

4.

Evaluate Environmental Factors: Temperature, altitude, and other environmental factors can impact a fuse's performance. Consult the manufacturer's guidelines to ensure that the selected fuse is suitable for the specific operating conditions.

What is the Difference Between AC and DC Fuses?

While AC (Alternating Current) and DC (Direct Current) fuses both serve the same primary purpose of protecting electrical circuits from overcurrent, there are key differences between the two:

1.

Current Flow: AC fuses are designed for use in circuits with alternating current, where the direction and magnitude of the current change periodically. In contrast, DC fuses are used in circuits with direct current, where the current flows consistently in one direction.

2.

Arc Extinguishing: When a fuse interrupts the current flow, an electrical arc forms as the fusible link melts. In AC circuits, the current naturally passes through zero at regular intervals, which helps extinguish the arc more easily. In DC circuits, however, the continuous current flow makes arc suppression more challenging, requiring specialized arc extinguishing techniques and materials in DC fuses.

3.

Voltage Ratings: AC and DC fuses often have different voltage ratings, even if their current ratings are the same. Due to the unique challenges associated with arc suppression in DC circuits, DC fuses generally have lower voltage ratings than their AC counterparts.

4.

Fuse Construction: The construction of AC and DC fuses may differ to accommodate the unique characteristics and requirements of each current type. For example, DC fuses often incorporate additional features, such as magnetic or mechanical arc suppression mechanisms, to enhance their performance in direct current circuits.

In conclusion, DC fuses play a crucial role in safeguarding electrical systems and equipment from overcurrent damage. By understanding the different types of DC fuses and their applications, as well as the factors to consider when selecting a fuse size, beginners can quickly build their knowledge and confidence in working with these essential devices. Additionally, recognizing the differences between AC and DC fuses can help ensure that the appropriate fuse is selected for each application, further enhancing the safety and efficiency of electrical circuits.